Books

The smell alone of books provides that moment of peace, of enjoyment. A book is tangible and always gives the reader that little bit more. You can flip through it forwards and backwards. You can sneak a peek at the last page, so as not to read the plot through and through yet. With a bookmark, you know where you left off when you have to do something else.

Books you keep. They are gifts for yourself or for someone else. When you give someone a book as a gift, you think about what they like to read. You browse through the books in a bookshop or search on the internet for that ideal book. Because you keep books, you can also go back to them.

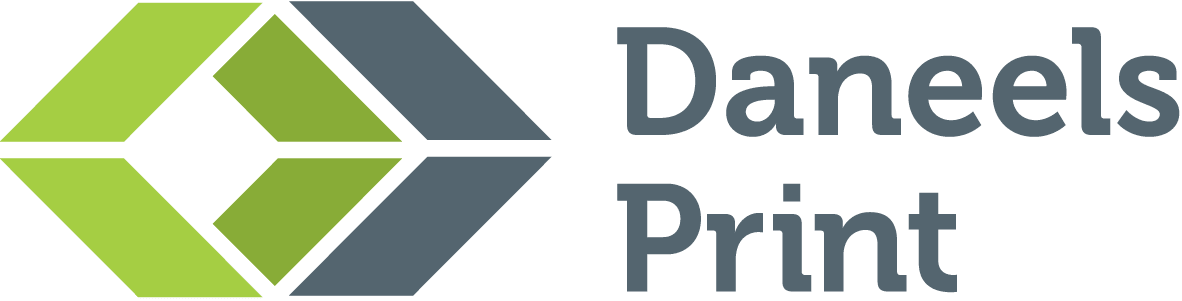

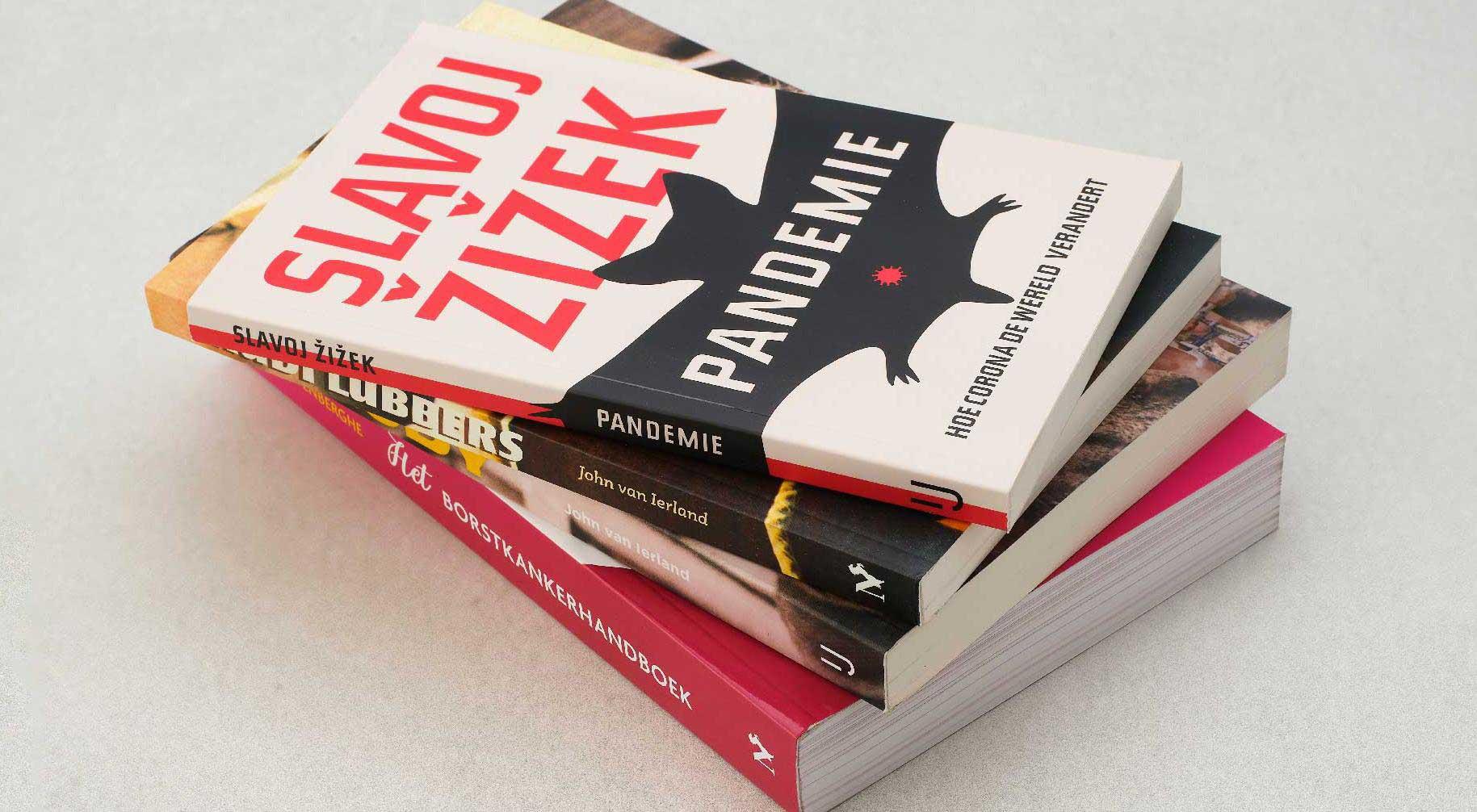

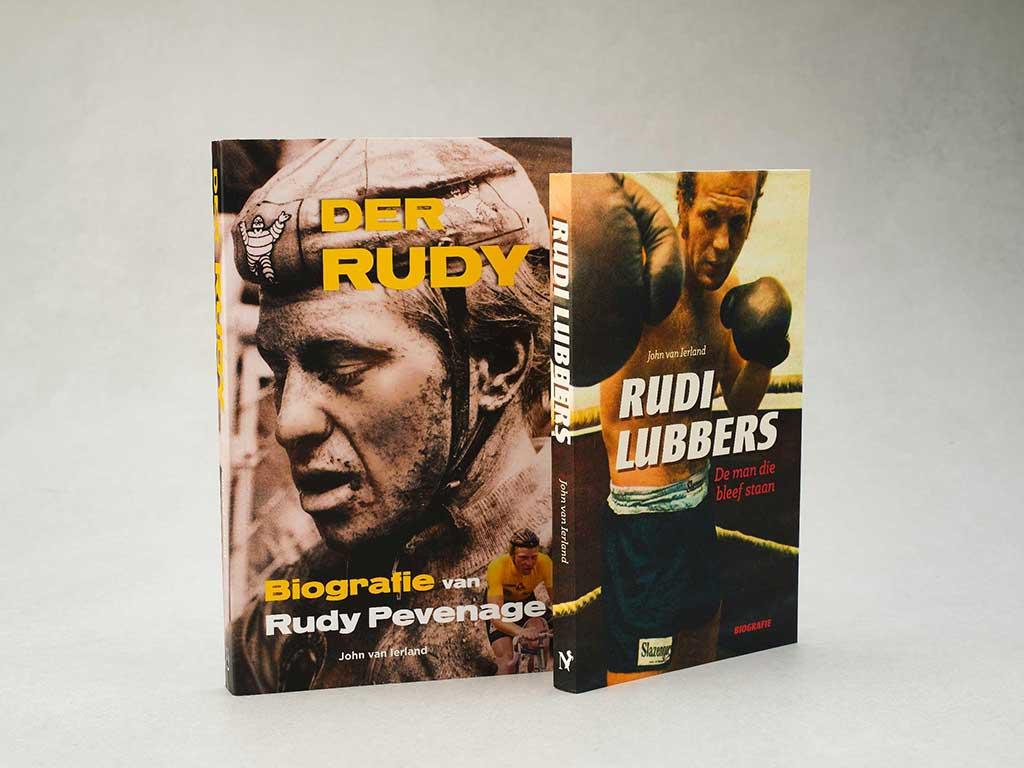

Graphic design of a book

A book has already gone through a complete process before it ends up in the shop or in an online provider's warehouse. Once the book is written, the design and layout for it become very important. We choose a book not only through the blurb on the back cover but also with our eyes. So the colours and design of a book are very important. Graphic designers make sure that the design matches the content. Colour, text and size are considered carefully.

Clients can supply the graphic design of a book, but they can also opt to outsource it to us. Brandle, our creative partner, is strong in the graphic design of books. In cooperation with the client, they provide a creative design that stands out from other books.

How are books printed?

Books are printed in small and large print runs. The offset technique is the highest quality way of printing to that end. So how are books printed?

1. Verification

The certified PDF files provided by our client or our partner Brandle, are first checked thoroughly so as to avoid problems during printing. A prepress technician determines the order of the pages on the printing plates and adds the print control strips.

2. Offset printing

The certified PDF files provided by our client or our partner Brandle are first checked thoroughly so as to avoid problems during printing. A prepress technician determines the order of the pages on the printing plates and adds the print control strips. A final check is then carried out with an online soft proof which is presented for approval to print. Offset printing uses a technique whereby water and ink repel each other. We print in CMYK (also called full colour or full-colour printing). Special, unique colours are also possible. these are known as PMS or Pantone colours.

CMYK stands for Cyan, Magenta, Yellow, Key (=Black). By combining these 4 basic colours, you can print all the colours of the rainbow. With CMYK, you split the colours into four basic colours. A printing plate is produced for each basic colour. Fine grids on the printing plates contain all the image information down to the minutest detail.

Those plates are mounted on the press, one plate per printing tower. The ink comes into contact with the plate, which is moistened. The places that have attracted the moisture repel the ink. The areas that have not absorbed any moisture are filled with the ink. A rubber cloth is used to transfer the ink to paper. The paper passes from to paper feed to the CMYK towers where the colours are combined for a final reproduction as in your print file.

The Daneels Media Group uses a unique Heidelberg LPL recto-verso technology. This enables us to print full colour, PMS and environmentally friendly dispersion lacquers in a single run. Both sides of the paper are printed recto and verso, at a rate of no fewer than 18,000 printing sheets per hour. Thanks to IR drying, the printing sheets come out of the press 'dry' and are immediately ready for further finishing. This results in very efficient setting times, a lot less paper and energy are required. Turnaround times are also shortened significantly as a result, so delivery times are improved as well.

3. Process of cutting, folding, gluing or sewing

The book's printing sheets are cut to size after printing. The correct dimensions are entered in our computer-controlled cutting machine in advance so the sheets are cut perfectly, with as little loss as possible.

A folding machine folds the printing sheets according to the pre-set folding method, e.g. 4, 8, 16 or 32 pages, depending on the final finish.

The folded quires are then collected and placed in the correct order on the glue line. All the quires together form one book block, which is glued together with the cover. We call this finish soft cover. Finishing in which the book block is sewn and provided with a cardboard cover is called hard cover.

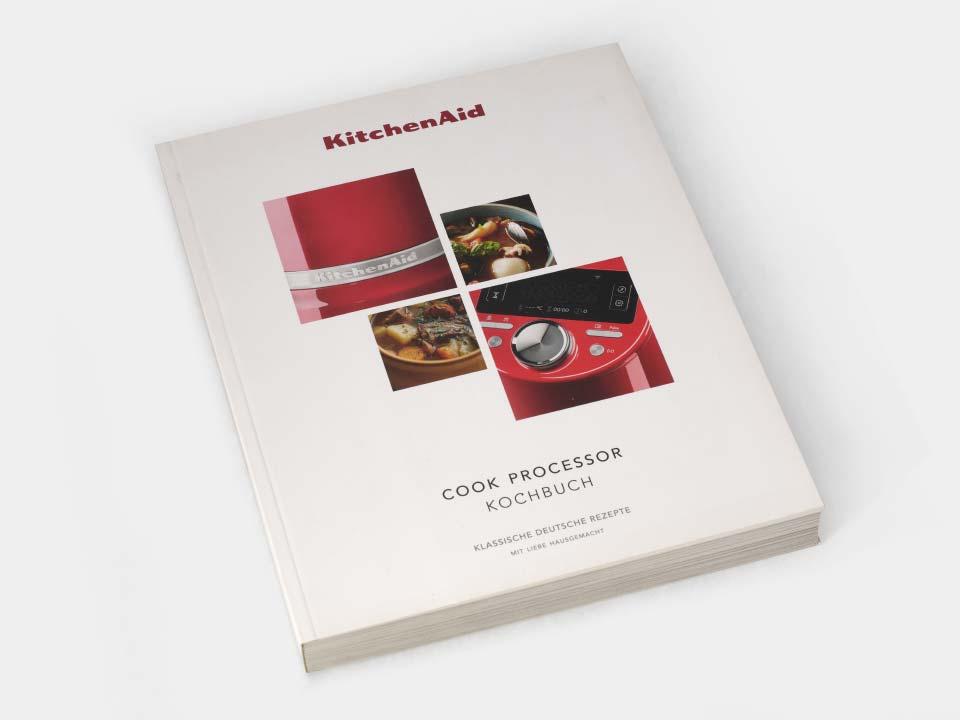

The outcome becomes even more luxurious when the book is finished with, for example, a ribbon, a capital band and a dust jacket.

4. Enhancing a book

Numerous enhancements make a book even more unique. A fabric capital band adds a luxurious detail to the spine. Adding a reading ribbon is perhaps also a good option. The thickness of the cardboard on which the printed cover is glued or 'cached' determines that special look and feel of the book. Extra luxury can be added by using gold foil or embossing details, for example.

The Daneels Media Group designs and prints books in the most sustainable way possible. For instance, we use bio-printing inks, FSC® or PEFC certified paper and cardboard, and we make sure that shipping books causes as little impact on our environment as possible.